Lift Stations from Applied Process

Reliable Pump Station Solutions for Any Application, from design and product selection, through start-up, training & warranty.

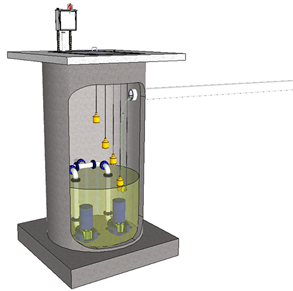

Applied Process has over 30 years of experience working with engineers, contractors, commercial, municipal and industrial customers alike to provide common sense solutions for pump and lift station applications of all types and sizes.

Engineers

Put our experience to work for you.

As an engineer you are dealing with countless variables in each new project you design. The key to designing a reliable pump station is in understanding how all the system components operate together. Not every pump will work in every application.

Let us help you choose the right combination of equipment for your lift station project. We can provide you with detailed technical specifications and recommendations and guidance on a wide range of applications.

Sometimes the answer lies with us, sometimes with one of the manufacturers we represent. Regardless, we don’t rest until a solution is found.

Contractors

We’ll help you keep on schedule and on budget.

We understand contractors like you are under tremendous pressure to win that next pump station bid. You don’t need surprises. You need dependable, competitively priced pump, control and storage tank packages, delivered on time and on budget.

You can count on Applied Process Equipment to help eliminate the guess work. Top of the line equipment, quick submittal turn-around, backed up with field start-up and commissioning, training and warranties.

Commercial, municipal & industrial customers

It all comes down to profitability.

We understand that reliability = productivity = profitability.

Applied Process Equipment represents the most trusted manufacturers of pump and pump station equipment. And, we have the expertise to help you find the best solutions for maximum life cycle performance.

High quality non-clog ball check valves (2” to 16” ductile iron & SS) that operate in any position.

Submersible grinder pumps and solids handling pumps.

Control panels, liquid level alarms, control & pump switches.

![]()

Vertical column metal sump pumps and non-cog industrial sewage pumps.

Aluminum, steel and stainless steel access doors and accessories.

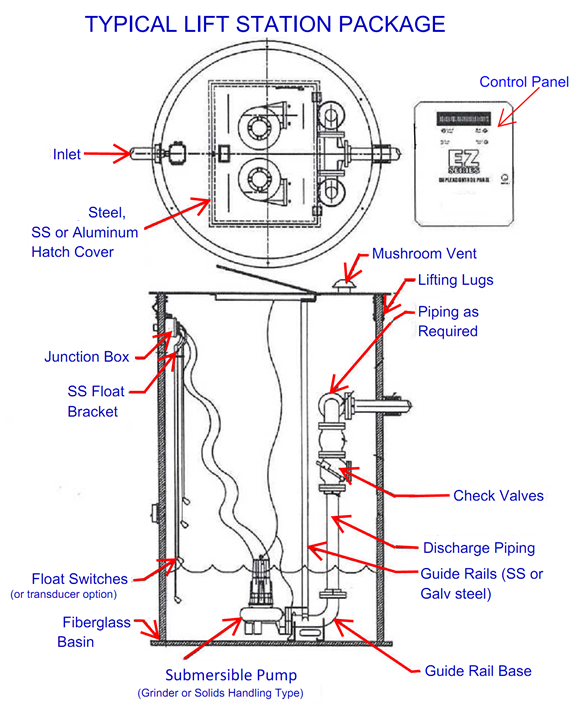

Selecting the right components is critical for lift station design. We can assist you in selecting and integrating the right equipment for your application.

Selecting the right components is critical for lift station design. We can assist you in selecting and integrating the right equipment for your application.

Elements To Consider:

| The Basin: | Properly sized for correct pump run time per cycle.

| The Pump: | Do the water conditions and and solids content require cast iron or stainless steel?

|

| Control Panel: | Correct appearance & traffic rating?

| Check Valves: | Failed check valves are the most common cause of pump failures. |

| The Cover: | Offers all required control features? | Rail System: | Correctly design for easy maintenance? |